On the Cutting Edge: Lab-on-a-Chip

By Werner Eberhardt, Product Manager, Agilent Technolgies

Contents

Introduction

Sophisticated Technology and Simple Operation

Sample-Chip Preparation Protocol

Automated Quantitation and Data Management

Follow-On Applications

Introduction (Back to Top)

During the past 30 years, the microelectronics industry has revolutionized laboratory instrumentation and data handling. In many respects, however, today's laboratory still resembles the 18th century workplace in which hands-on chemists used scientific apparatus to shed light on the nature of the unseen universe. Laboratory instrumentation now encompasses nanoscale chemistry and microfluidics. The result: laboratory on a chip.

To turn the Lab-on-a-Chip concept into a working technology required borrowing a page from the world of microprocessor fabrication as well as developing microfluidics—an engineering discipline that adapts fluid transport and analyte partitioning to chip-based architectures. The groundbreaking development work and prototyping of the Lab-on-a-Chip concept (also known as LabChip technology, the analytical microchip, or the chemical microchip) were spearheaded by Caliper Technologies Corp. (Mountain View, CA).

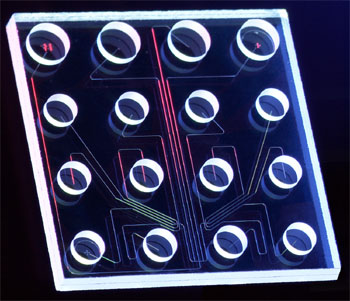

The first commercial products using this technology have reached the analytical laboratory market in September 1999 through the collaboration of Agilent and Caliper Technologies. LabChip technology consists of networks of channels generated in a microchip. The channels serve as fluid pathways for carrying out experimental and/or analytical protocols. Microelectrodes that interface with each chip generate voltage gradients that simulate the action of pumps and valves and enable the precise metering of reagents and samples. The potential gradients also allow the control of fluid transport for performing on-chip analytical procedures such as partitioning and purification (Figure 1).

Figure 1: LabChip device, the first commercial example of microfluidic technology for the analytical laboratory.

As evidenced in microelectronic applications, downsizing the scale of operations brings a host of benefits, because chip formats require far smaller fluid volumes than conventional laboratory-scale operations. Chip-based experimental protocols significantly reduce the required volume of both sample and reagents. Analyte partitioning within the chip's reduced dimensions cuts analysis times because of the much shorter travel distances required. At the same time, resolution is often improved because heat generated from the use of relatively large voltage gradients can be dissipated more efficiently from the small-diameter fluid channels. By linking and automating all the procedures in a protocol, sample loss is minimized, and many of the errors arising from manual transfer and handling operations or individual experimental differences are eliminated. As a result, sensitivity and reproducibility are improved while overall operational costs are reduced. Reproducibility is further enhanced by the tight specifications under which the chips are manufactured.

LabChip technology offers greater flexibility and is easier to use than conventional analytical platforms. Changing a method consists of simply using a different type of chip in combination with a different automated software protocol. Sample handling, analyte separation, detection, quantitation, and subsequent data processing are all integrated within the same hardware-software assembly. This integration makes it possible to design instruments with a much broader range of applications and garners additional savings by reducing the need for a full complement of application-specific hardware or periodic system upgrades.

In 1998, Caliper Technologies and Hewlett-Packard (now Agilent Technologies) formed an alliance. This relationship draws on Agilent's expertise in analytical instrumentation and data management and Caliper's expertise in LabChip technology as well as on Agilent's extensive sales and support network to develop and market systems based on LabChip technology.

Sophisticated Technology and Simple Operation (Back to Top)

Initial LabChip-based applications are targeted to the life sciences and pharmaceutical industry, in which the demand for higher throughput, better-quality results, and lower cost is intense. The first platform designed for use with LabChip technology is the Agilent 2100 bioanalyzer, an integrated nucleic acid analysis system that adapts traditional gel electrophoresis principles to a 12-well analytical microchip format (Figure 2). The instrument houses the chip, provides electrical power to run the analysis, and incorporates an optical system that detects analytes. Signals from the detector are sent to a PC outfitted with application-specific software, which collects, processes, analyzes, stores, and distributes the data.

Figure 2: The Agilent 2100 Bioanalyzer, the first platform designed for use with LabChip technology.

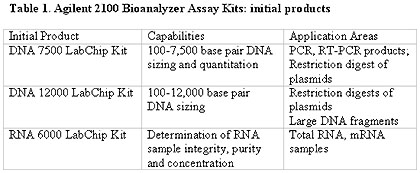

The 2100 bioanalyzer is currently provided with application kits for either DNA or RNA analysis assays. The primary applications for the DNA kits include analysis of PCR products and restriction digests, whereas the RNA kit can be used to assess the quality of various total and messenger RNA preparations. The range of LabChip products will be expanded, and new kits and other applications will be added. Table 1 provides general specifications for current LabChip products.

Sample-Chip Preparation Protocol (Back to Top)

All the ingredients necessary to run an analysis, including chips and reagents, are provided with each assay kit. After reagent preparation, the chip is loaded with a separation gel containing an intercalating dye. Next, all remaining wells are filled with the appropriate sample buffer, which ensures contact with the electrodes located in the lid of the instrument. The sizing ladder, which is used to calibrate the system, is then added to a designated ladder well. Finally, the 12 samples are loaded onto the chip. This entire operation requires less than 5 min to complete. The prepped and loaded chip is placed into the instrument's chip holder. Closing the cover causes the electrodes to be inserted into the chip wells, creating an integrated electrical circuit. Each electrode is connected to an independent power supply for maximum control and flexibility. Samples from each well are sequentially moved into the chip's central separation channel. As the sample moves down this channel fragments separate by size in about 90 s, and their signal is detected with excellent measurement sensitivity. As each nucleic acid fragment is detected results are transmitted directly to the system software.

Automated Quantitation and Data Management (Back to Top)

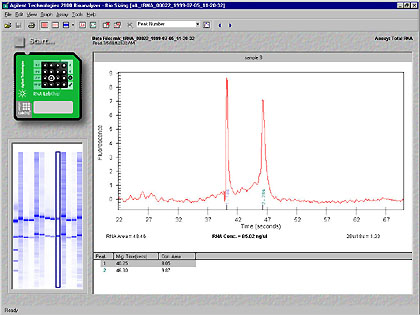

During sample analysis, the system software processes the detector readout and generates electropherograms for each sample. Results can be graphically displayed as electropherograms, as simulated gels, or in tabular form (Figure 3). Fragment lengths are determined from the calibration curve of size in base pairs versus migration time computed from the data generated by the DNA ladder. In addition to fragment size, the software computes fragment concentration by calculating the ratio of the peak area to an internal standard. An overlay feature enables users to graphically compare results from any wells, including the ladder.

Figure 3: The Agilent 2100 Bioanalyzer displays results in a gel-like image and/or as electropherograms. An overlay feature enables users to graphically compare results from any wells, including the ladder run in the first well.

Typically nucleic acid fragment size and concentration are determined in one-half to one-third the time of conventional gel separation technology, with better sensitivity and reproducibility. Another feature of LabChip technology is minimal sample consumption. This advantage is especially welcome for RNA samples, which can be expensive, difficult to obtain and time-consuming to purify. The RNA LabChip assay integrates analysis of the quality and concentration of total RNA and mRNA preps.

All the data from a chip run, including instrument settings and analytical results, are stored in digital format by the bioanalyzer software for subsequent processing and network distribution to other users. File data may be printed in various formats and exported as an ASCII file for use with other data analysis software, including spreadsheet programs such as Microsoft Excel. The ability to electronically capture and transmit instrument settings and experimental data ensures that comparable determinations can be run at other locations under exactly the same conditions.

Follow-On Applications (Back to Top)

The first commercial implementation of Lab-on-a-Chip technology demonstrates that this new minimized, integrated approach to analysis can greatly enhance the quality of results while reducing the time and effort required to carry out analytical protocols. Although the first types of chips are designed for nucleic acid application, one can expect to see additional applications in biochemical analysis. In fact this technology will prove to be an important analytical tool throughout the pharmaceutical and biotech industry for applications in drug discovery and development, including high-throughput screening, compound profiling, clinical trials, manufacturing, and postmarket surveillance.

Analytical applications, however, are only the first step in the transformation of the chemical laboratory. LabChip technology has the potential to replace broad areas of hands-on experimental chemistry. Work on these approaches is now being pursued vigorously (Figure 4). When further commercial applications become available, we will all experience the reality of this new laboratory paradigm—the lab on a chip

Figure 4: Electroosmotic fluid being pumped at approximately 1 nl/s through a LabChip device at a channel intersection of 80 µm (w) x 10 µm (d). Fluid flow at the intersection is electrokinetically controlled from all four directions simultaneously. Strength and phasing of voltage gradients enable emulation of the action of valves and pumps that can drive on-chip experimental procedures such as reagent dispensing and mixing, reaction(s), product separation, and purification.

About the Author

Werner Eberhardt is product manager of Agilent Technolgies' Lab-on-a-Chip Products and is based in Waldbronn, Germany.